High speed and flow rates of highly abrasive grain in transfer chutes and pipes can cause extreme wear and damage to steel surfaces of equipment.

Grain handling facilities include a wide range of different equipment to receive, store, transport, process and ship bulk raw agricultural grain. Due to the highly abrasive nature of some grains, this equipment is often subjected to extremely high wear during operation. This wear can damage steel surfaces of equipment potentially causing unwanted downtime and loss of production or possibly dangerous and wasteful spillage.

Reglin CERA-WEAR Ceramic lining will protect grain handling chutes and pipework from abrasion without reducing flow.

Wear protection linings are commonly used on grain handling equipment to protect it from abrasion. Rubber and Polyurethane linings are an effective solution in many cases, however some critical applications which are exposed to higher flow rates or more abrasive grain will require something with greater wear resistance. Ceramic lining critical equipment such as loading chutes and transfer pipes will protect it from this extreme abrasion, offering a longer lasting wear protection solution without restricting flow.

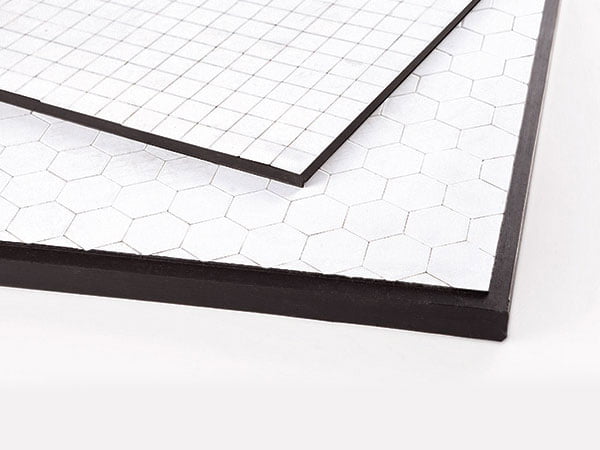

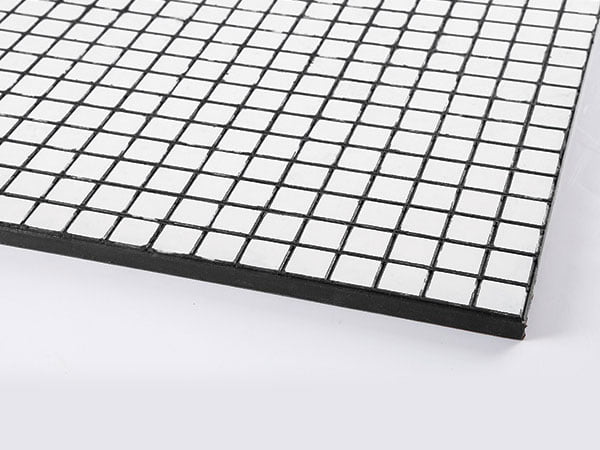

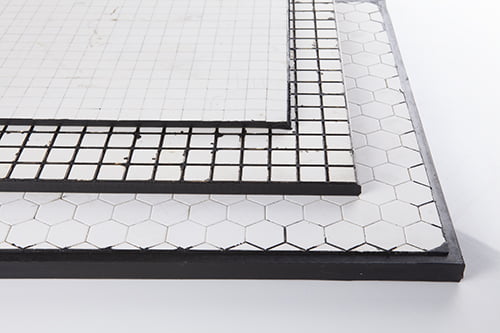

Reglin offers a comprehensive range of CERA-WEAR rubber backed ceramic wear pads made from our premium 92% alumina tiles. CERA-WEAR Ceramic wear pads are extremely flexible for installation and offer the highest level of abrasion and impact resistance for grain equipment lining.

Rubber backing for flexibility

CERA-WEAR Ceramic wear pads feature a 40 Duro rubber and are extremely flexible. Available in 500x500mm pads with a variety of different tile types, they are easy to handle and can be easily installed on flat, convex or concave surfaces of grain handling equipment.

CN bonding layer offers easy on-site installation

CERA-Wear Ceramic wear pads are easy to apply without any special equipment. They feature a specially formulated Neoprene based CN bonding layer to achieve ultimate adhesion when bonded to steel or rubber surfaces. The CN bonding layer and cold vulcanising adhesive system is extremely flexible. It allows for good bond strength to be achieved even in adverse conditions encountered on site.