Reg-Lag FG Sheet Lagging is a premium food grade 60 Duro rubber pulley lagging sheet with CN bonding layer

FEATURES

Reg-Lag FG Sheet Lagging is made from a blended nitrile rubber compound and will display good resistance to food-based greases including a range of animal fats and plant-based oils. It also displays good resistance to abrasion and will improve the coefficient of friction between the pulley and belt, reducing slippage.

Reg-Lag FG is tested and conforms to FDA 21 CFR 177.2600 “Rubber articles intended for repeated use”. This makes it suitable for contact with dry, aqueous and fatty foods as defined by the FDA.

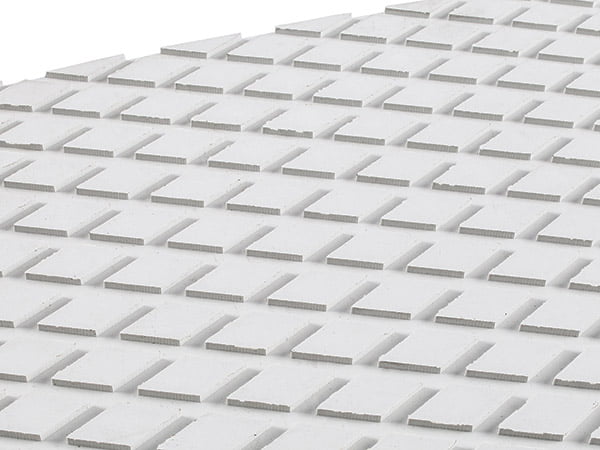

Reg-Lag FG Sheet Lagging features a diamond profile surface. This design prevents material buildup and assists with shedding dirt and water away from the pulley. It is supplied in roll form for easy application to the pulley in a single sheet.

Reg-Lag FG features a specially formulated Neoprene based CN bonding layer to achieve ultimate adhesion when bonded to steel or rubber surfaces. The CN bonding layer is compatible with a wide range of Neoprene based rubber adhesives and allows for good bond strength to be achieved even in adverse conditions encountered on site.

STANDARDS

Reg-Lag FG (FDA) Sheet Lagging conforms with FDA 21 CFR 177.2600.

As stated in FDA CFR 21.177.2600. In accordance with good manufacturing practise finished rubber articles intended for repeated use in contact with food shall be thoroughly cleansed prior to their first use in contact with food.

APPLICATIONS

Reg-Lag FG Sheet Lagging has been designed primarily for use as a wear and corrosion protection lining for conveyor pulleys.

It can be used on a wide range of conveyor system pulleys and is designed for use in low and medium belt tension applications.

Reg-Lag FG Sheet Lagging is suitable for use in hygienic environments such as food and drink manufacturing, handling or storage facilities.

It is bonded to conveyor system pulleys to protect their surface from abrasion and to improve pulley wear life. Pulley lagging will reduce belt slippage and improve drive performance and tracking of conveyors.

TECHNICAL INFORMATION

| Polymer | NR/NBR | |

| Colour | White with CN bonding layer | |

| Specific Gravity | 1.15 | ASTM D297 |

| Hardness | 60° ± 5° Shore A | ASTM D2240 |

| Tensile Strength | 10 MPa (min) | ASTM D412 |

| Elongation @ Break | 500% (min) | ASTM D412 |

| Abrasion | 250 mm³ (max) @ 10N | ASTM D5963 |

| Temperature Range | -20°C to +70°C | |

| Tear Strength | 40 N/mm (min) | ASTM D624 |

AVAILABLE SIZES

Reglin Stock Reg-Lag FG Sheet Lagging in a standard thickness and roll size.

| PART NUMBER | DESCRIPTION | WEIGHT (PER L/M) |

| DLW081500M | Reg-Lag FG (FDA) Sheet Pulley Lagging (Mini Diamond) 8mm x 1500mm with CN B/L (10 L/M Rolls) | 18.8 kgs |