Premium grade wear and impact resistant 70 Duro rubber bar with an embedded aluminium T-Track

FEATURES

Regline WB Rubber Wear Bars are made from a highly elastic premium rubber compound and will display excellent resistance to sliding abrasion and large particle impact.

Offering superior wear protection for your equipment these bars will also reduce vibration and lower noise levels and dust emissions by absorbing energy from the impact of materials.

Our rubber wear bars are supplied with aluminium T-Tracks for added stability. They are lightweight and allow for strong and easy mechanical fastening to equipment.

Regline WB Rubber Wear Bars can be supplied as a custom engineered wear protection rubber lining system for your industrial equipment. They are suitable for high wear and moderate impact applications.

APPLICATIONS

Regline WB Rubber Wear Bars have been designed primarily for use as a wear protection rubber lining system for industrial applications.

They are installed into industrial equipment to protect steel surfaces from abrasion and impact. Primarily used in the mining, quarrying and mineral processing industries, they are typically used on the following equipment:

- Chutes and Feed Spouts

- Rock Boxes

- Hoppers and Surge Bins

- Launders

- Cyclones

- Feeders

- Screens

- Mills and Scrubber Mills

- Trunnions

- Conveyor Transfer Chutes and Deflector Plates

These rubber wear bars can also be used for any application which requires a mechanically fastened wear and impact resistant rubber bar including:

- Lifter Bars in Mills and Scrubbers

- Centre Clamp Bars in Screens

- Marine and Transport Docking Fenders

- Anti-vibration Mounts

TECHNICAL INFORMATION

| Polymer | NR/BR | |

| Colour | Black with aluminum track | |

| Specific Gravity | 1.13 | ASTM D297 |

| Hardness | 70° ± 5° Shore A | ASTM D2240 |

| Abrasion | 80 mm³ (max) @ 10N | ASTM D5963 |

| Tensile Strength | 17 MPa (min) | ASTM D412 |

| Elongation @ Break | 350% (min) | ASTM D412 |

| Temperature Range | -20°C to +70°C |

AVAILABLE SIZES

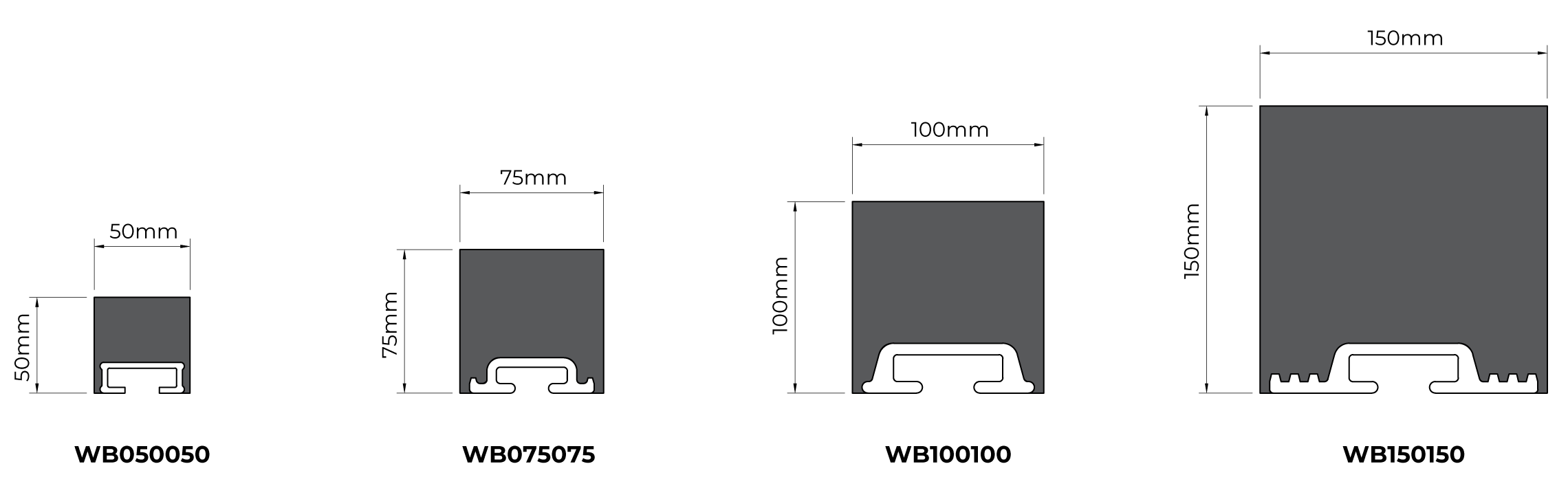

We supply Regline WB Rubber Wear Bars in a range of standard sizes. They are supplied with embedded aluminium T-Tracks designed to be fastened with T-Bolt Assemblies. These bars can be supplied custom cut as per specifications and drawings. We can also custom mould rubber bars to suit your specific requirements.

| PART NUMBER | DESCRIPTION | WEIGHT (EACH) | TECHNICAL DRAWING |

| WB050050 | Regline WB Rubber Wear / Lifter Bar 50mm x 50mm x 1500mm with AL-44 T-Track | 4.1 kgs | |

| WB075075 | Regline WB Rubber Wear / Lifter Bar 75mm x 75mm x 1500mm with AL-65 T-Track | 10.3 kgs | |

| WB100100 | Regline WB Rubber Wear / Lifter Bar 100mm x 100mm x 1500mm with AL-90 T-Track | 18.4 kgs | |

| WB150150 | Regline WB Rubber Wear / Lifter Bar 150mm x 150mm x 1500mm with AL-140 T-Track | 40.2 kgs |