In mining and mineral processing, curved equipment surfaces, such as cyclone launders, tanks, slurry piping, and hoppers, are commonly protected with rubber lining to reduce wear. However, in applications where abrasion and impact are more severe, standard rubber lining alone often doesn’t provide the durability required.

Traditional rigid ceramic or steel liners, while more wear resistant, are typically too inflexible to suit the shape of curved components, leading to installation issues, poor fitment, and premature failure.

Reglin Cera-Wear Ceramic Wear Pads solve this problem by combining the wear performance of 92% alumina ceramic tiles with the flexibility of premium rubber backing, allowing them to conform to curved surfaces without compromising protection.

Why Choose Cera-Wear Ceramic Wear Pads?

The Flexible Alternative to Rigid Liners

Cera-Wear Pads are manufactured using 40 Duro rubber backing, giving them superior flexibility and resilience. Unlike rigid liners, they can bend and follow concave and convex curves, making them ideal for applications where equipment geometry rules out standard ceramic panels.

Designed for Curved and High-Wear Surfaces

These pads are purpose-built for installation on cyclone launders, tanks, pipes, elbows, complex hoppers and cones, areas where traditional rubber is no longer durable enough, but rigid ceramic cannot be installed effectively.

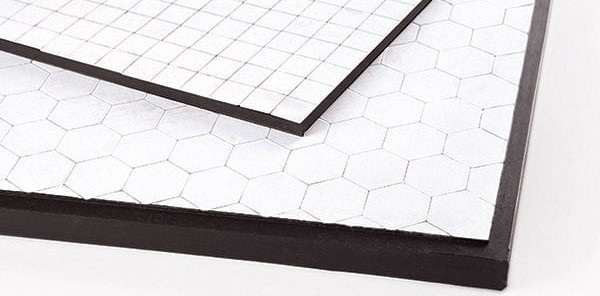

Available in a range of tile configurations

With no spacing between tiles, ideal for mildly curved or flat surfaces resulting a full 100% Ceramic coverage surface.

Cera-Wear SR Ceramic Wear Pads:

With rubber between each square shaped tile for added flexibility, ideal for tighter curves and more complex geometries. Square tiles allow for easy cutting with hand knives for easy installation on site

Cera-Wear HR Ceramic Wear Pads:

With rubber between each Hexagonal shaped tile for added flexibility and the highest level of impact resistance, ideal for tight curves and more complex geometries with high wear and impact.

Outstanding Wear and Impact Resistance

Each pad contains fully vulcanised 92% alumina ceramic tiles, offering extreme resistance to sliding abrasion, fines, and slurry flow. The rubber layer beneath and around the tiles absorbs impact forces, protecting both the tiles and the structure.

Easy Cold Bonding – No Structural Modification Needed

Cera-Wear Pads come with a CN bonding layer, allowing them to be bonded with adhesive in a workshop or on-site. This method eliminates the need for drilling holes or welding brackets, preserving structural integrity and making them ideal for retrofit projects or shutdown maintenance. View Rubber Adhesives and Primers available from Reglin.

Lightweight and Easy to Handle

Compared to steel-backed alternatives, Cera-Wear Pads are lighter and easier to install, especially in confined or elevated areas. This simplifies handling and improves safety during installation.

The Result: Flexible, Long-Lasting Protection for Curved Surfaces

By using Reglin Cera-Wear Pads, sites benefit from:

- Extended wear life on equipment with curved or irregular surfaces

- Reduced installation time—no welding, drilling, or custom fabrication

- Improved safety and handling due to lightweight construction

- Lower maintenance costs and fewer liner changeouts

Conclusion

When rubber lining no longer provides enough protection and rigid liners are too difficult to fit, Cera-Wear Ceramic Wear Liners deliver the perfect combination of flexibility, strength, and easy installation. Designed to suit both mild and extreme curves, they are the trusted choice for mining and mineral processing operations across Australia looking to extend equipment life and improve wear performance in the toughest conditions.

Talk to the Reglin team today to find out how Cera-Wear can improve your curved surface wear protection.