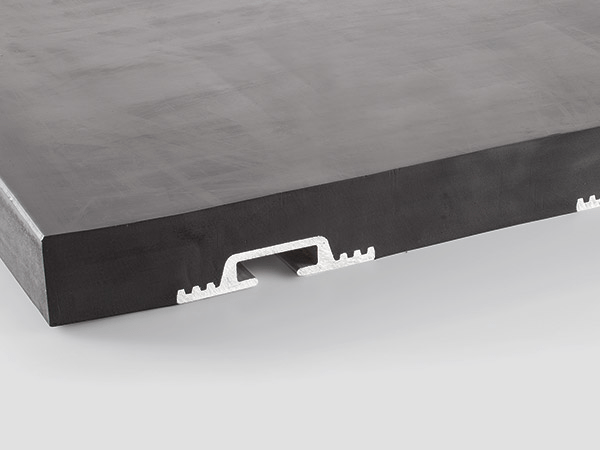

Regline PP Rubber Wear Plates and WB Rubber Wear bars were used to create a rock-box lining system to protect a screen underflow chute from high flow abrasion wear.

CHALLENGE

To supply a cost-effective durable wear liner system which would increase life of equipment and reduce total maintenance costs.

A new wear liner solution was required for a Screen underflow chute critical to the processing operation at a gold mine. The hardened steel liners being used currently were not lasting between shutdown cycles and were completely worn through regularly. This was damaging the structure of the chute and causing unscheduled shutdowns and loss of production. The Main Screen underflow chute was being subjected to extreme wear due to the high flow rates of ore being processed through the Screen directly impacting the chutes walls. The ore included highly abrasive fines up to medium sized rock.

Regline PP Rubber Wear Plates were installed initially which worked well and lasted longer than existing steel liners. Due to the critical nature of the chute and the high costs associated with liner change-outs, a more durable and longer lasting wear liner solution was desired by the mine.

OUTCOME

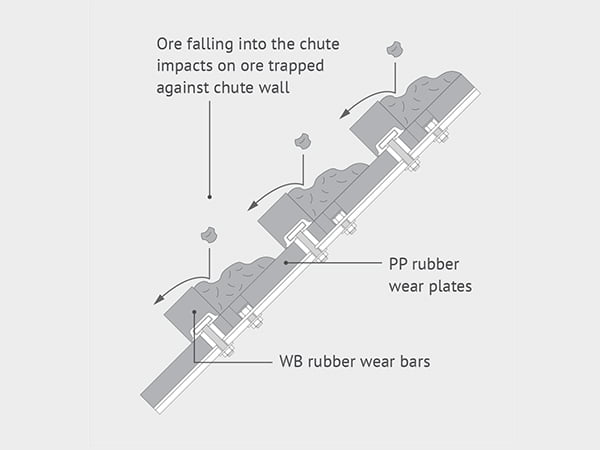

Regline Rubber Wear Liners were installed to protect equipment by utilizing a rock on rock impact design.

Reglin Rubber supplied Regline PP Rubber Wear Plates and WB Rubber Wear Bars which were installed into the Chute in a rock-box design as a wear liner solution against the combined abrasion and impact of the ore.

Rubber liners and bars were mechanically fastened onto the existing angled walls of the chute in a configuration which created a series of rock ledges. These ledges trapped ore against the chute wall resulting in less actual impact of ore against the liners as new ore flowing through the chute made impact against the trapped ore creating a rock on rock effect.

The combination of the premium wear resistant rubber lining absorbing the impact energy of the ore and the reduced abrasion on liners due to the rock-box design proved to give much better durability and have lasted significantly longer than previous steel liners designs.

The design of the plate and bar configuration also meant wear occurred only on limited parts of the liners and allowed them, once finally worn, to be easily rotated for re-use within the chute, resulting in less required replacement liners.

The result of using Regline Rubber wear liners to create a Rock box design was an effective solution. The reliability of the equipment was improved and increased productivity of the screen and mining process. This outcome offered value to the customer by increasing durability of equipment lining whilst reducing ongoing maintenance costs and potential unwanted downtime.