In high-impact and high-wear environments like quarries and hard rock mining operations, screening equipment plays a critical role in site productivity. Traditionally, wire mesh screen mats, steel screen tension side clamp bars and centre hold-down bars have been used. Whilst economical to purchase, these components are prone to fast wear, impact damage, and will generate high noise levels during screen operation.

Reglin’s rubber screening solutions offer a superior longer lasting alternative. From rubber screen mats to rubber lined clamp bars and steel backed rubber hold-down bars, these products are designed specifically to withstand the punishing demands of aggressive screening conditions. Using rubber screening components not only extend service life of the components themselves but also improve safety, reduce noise, and lower overall maintenance costs due to reduced change-outs.

Why Rubber is the Ideal Material for Screening Systems

In quarrying and hard rock mining operations, screens are constantly exposed to wear and impact from sharp, heavy rock at high flow rates. Rubber is highly elastic and energy-absorbing, offering significant advantages over steel and wire components in these tough applications, including:

Superior Impact and Abrasion Resistance

Rubber screen mats and components will absorb and dissipate the energy from rock, reducing structure damage and extending screen life, whilst also lasting significantly longer than standard products.

Noise Reduction

Noise from rock on metal contact and high vibration is a major safety concern. Rubber’s natural damping properties significantly reduce operational noise, creating a safer working environment and helping meet noise control requirements in populated or enclosed sites.

Improved Safety and Handling

Rubber products are lighter and easier to install than steel alternatives, reducing manual handling risks and improving site safety during screen maintenance.

Corrosion and Chemical Resistance

Rubber resists corrosion and the effects of wet material, acidic fines, and chemical exposure often present in mineral processing circuits.

Enhanced Uptime

By increasing the wear life of screen panels and mounting components, rubber systems reduce maintenance frequency and unplanned downtime.

Custom Engineered Screening Solutions to suit any equipment

At Reglin, we supply custom-engineered rubber screening components designed to suit your existing equipment and screening requirements. Our rubber screen mats, clamp bars, and hold-down strips can be manufactured to match your screen’s dimensions and fastening systems, meaning no structural modification is required. With local manufacturing capabilities and extensive stock holdings in Australia, we can supply our high-quality rubber products with short lead times, helping you keep your operations running without carrying excessive stock of spare parts.

Rubber Screening Products for Complete System Upgrade

Rubber Screen Cloths (Cross-Tensioned or End-Tensioned)

- Available in a variety of thicknesses, aperture sizes and profiles to replace replace standard wire screen mats

- Abrasion and impact resistant and will withstand sharp, coarse material.

- Reduce pegging and blinding due to flexibility

- Self-cleaning action for consistent throughput

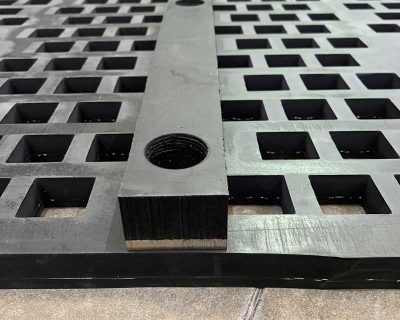

Rubber Centre Hold-Down Bars

- Used down the centre of the vibrating screen to secure screen mats

- Made from durable SAR 60 Rubber with a vulcanised steel backing plate

- Protect Hold down bolt heads and absorb impact from rock reducing stress on the screen deck.

- Prevents cracking and fatigue that occur with rigid steel bars

Rubber Lined Tensioning Side Clamp Bars

- Designed to grip the screen mat hooks and fasten to the side plates

- Rubber lined in our premium SAR 60 Rubber using hot vulcanisation for ultimate adhesion.

- Offer a much longer service life than standard steel side clamp bars.

- Lightweight and easy to install

Conclusion

Rubber is the smart upgrade for screening systems in the quarry and hard rock mining industries. By replacing conventional wire screen mats, steel centre hold-down bars, and side clamp bars with Reglin’s rubber solutions, operators can significantly improve durability, reduce maintenance downtime, enhance safety, and boost overall site efficiency.

If you’d like help specifying the correct rubber screening components for your site, contact the Reglin team today.