Cera-Grip LT Ceramic Strip Lagging is a premium grade wear resistant composite ceramic pulley lagging strip with CN bonding layer.

FEATURES

Cera-Grip LT Ceramic Strip Lagging is made from a highly elastic premium natural rubber compound. It contains embedded wear resistant alumina ceramic tiles for extreme abrasion resistance.

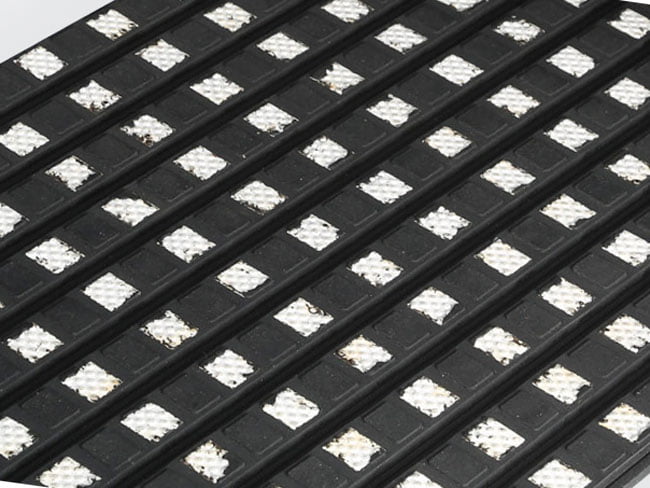

Cera-Grip LT contains dimpled ceramic tiles which maximizes the coefficient of friction between the pulley and conveyor belt. Each ceramic tile contains rubber around all sides for ultimate adhesion within the lagging and to allow flexibility of the tile. This flexibility ensures the tile can contact the belt correctly ensuring maximum grip whilst reducing wear to the conveyor belt cover.

Cera-Grip LT Ceramic Strip Lagging features 23% Ceramic tile coverage and a grooved profile surface.

Cera-Grip LT Lagging features a CN bonding layer to achieve ultimate adhesion when bonded to pulley surfaces and allows for good bond strength to be achieved even in adverse conditions encountered on site. It is compatible with a wide range of cold bonding rubber adhesives.

Cold Bonding Adhesives

Reglin stock Cold Bonding Adhesives proven for compatibility with our CN Bonding layer.

APPLICATIONS

Cera-Grip LT Ceramic Strip Lagging has been designed primarily for use as a wear and corrosion protection lining for conveyor pulleys.

It is designed to be cold bonded to pulleys to increase friction and to protect the pulley surface from abrasion, improving performance and pulley wear life.

The Cera-Grip design prevents material buildup and assists with shedding dirt and water away from the pulley, reducing belt slippage and improving drive and tracking of conveyors.

It is supplied in strip form for easy application, in-situ without removing the conveyor belt if required.

Cera-Grip Ceramic Strip Lagging is predominantly used in the Mining, Quarrying, Recycling and Mineral processing industries.

It is designed specifically for use on conveyor system drive pulleys operating in extreme conditions, including wet, dirty or dusty environments. It is suitable for use on long conveyor systems and in medium and high belt tension applications.

TECHNICAL INFORMATION

| Polymer | NR/BR | |

| Colour | Black with CN bonding layer | |

| Specific Gravity | 1.10 | |

| Hardness | 60° ± 5° Shore A | ASTM D2240 |

| Tensile Strength | 20 MPa (min) | ASTM D412 |

| Elongation @ Break | 450% (min) | ASTM D412 |

| Abrasion | 90 mm³ (max) @ 10N | ASTM D5963 |

| Temperature Range | -20°C to +70°C | |

| Tear Strength | 80 N/mm (min) | ASTM D624 |

| Ceramic Tile | 92% Alumina content |

| Density | 3.65 g/cc | ASTM C373-99 |

| Hardness (Rockwell) | 77 R45N | ASTM C1327 |

| Compressive Strength | 1950 Mpa (min) | ASTM C1424-04 |

| Flexural Strength | 320 Mpa (min) | ASTM C1161-02c |

| Water Absorption | 0% | ASTM C373-88 |

| Abrasion by Impingement | 0.05 grams (max) | |

| Abrasion by Rubbing | 0.1 grams (max) |

AVAILABLE SIZES

Reglin stock Cera-Grip LT Ceramic Strip Lagging in an industry standard thickness and roll size.

| PART NUMBER | DESCIRPTION | WEIGHT (PER L/M) |

| CPLRLT | Cera-Grip Light Ceramic Strip Pulley Lagging 12mm x 385mm (10 L/M Rolls) | 6.5 kgs |