Premium grade wear resistant composite ceramic liner with a CN bonding layer

FEATURES

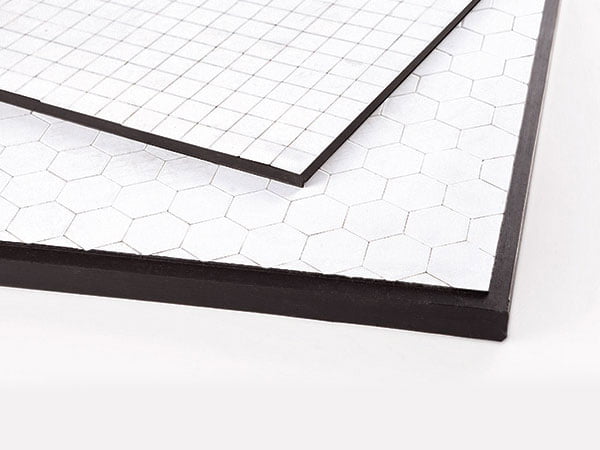

Cera-Wear Ceramic Wear Pads are made from wear resistant 92% alumina ceramic tiles vulcanised to a rubber backing. They display excellent resistance to both high velocity and high flow wet slurry and fine particle sliding abrasion and impact.

These ceramic liners feature ceramic tiles without gaps between them and are vulcanised to a 40 Duro premium natural rubber compound backing. This design creates a full 100% ceramic surface eliminating any possibility of fine particle wear between tiles. Cera-Wear Ceramic Wear Pads will give moderate impact resistance and flexibility and are suitable for installation on flat, mildly convex or concave surfaces.

They also feature a specially formulated Neoprene based CN bonding layer to achieve ultimate adhesion when bonded to steel or rubber surfaces. This CN bonding layer is compatible with a wide range of Neoprene based rubber adhesives and allows for good bond strength to be achieved even in adverse conditions encountered on site.

APPLICATIONS

Cera-Wear Ceramic Wear Pads have been designed primarily for use as a wear protection ceramic lining system for industrial applications.

These ceramic liners are bonded to industrial equipment to protect steel surfaces from abrasion and impact. They are predominantly used in the mining, quarrying and mineral processing industries, typically on the following equipment:

- Chutes

- Tanks and Pipework

- Conveyor Loading and Transfer Hoods

- Feeders

- Screen Beams and Components

- Cyclones

- Launders

- Flotation Cells

- Mill Feed Chutes

- Sumps and Underpans

Our ceramic wear pads are also used extensively throughout the agriculture industry on a range of grain handling, processing and storage equipment.

TECHNICAL INFORMATION

| CERAMIC TILE | ||

| Alumina Content | 92% (min) | |

| Density | 3.65 g/cm³ | ASTM C373-88 |

| Hardness (Rockwell) | 77 R45N | ASTM C1327 |

| Compressive Strength | 1950 Mpa (min) | ASTM C1424-04 |

| Flexural Strength | 320 Mpa (min) | ASTM C1161-02c |

| Water Absorption | 0% | ASTM C373-88 |

| Abrasion by Impingement | 0.05 grams (max) | |

| Abrasion by Rubbing | 0.1 grams (max) | |

| RUBBER | ||

| Polymer | SBR | |

| Colour | Black | |

| Hardness | 40° ± 5° Shore A | ASTM D2240 |

AVAILABLE SIZES

We supply Cera-Wear Ceramic Wear Pads in 500mm x 500mm panels in a range of standard thicknesses. They can also be supplied as a custom made bolt in ceramic wear liner system to suit your equipment and application requirements. See Custom Made Steel Backed Ceramic Liners for further information.

| PART NUMBER | DESCRIPTION | WEIGHT (EACH) | TECHNICAL DRAWING |

| CWP05/0302S | Cera-Wear Ceramic Wear Pad with CN B/L 5mm x 500mm x 500mm (Square pattern 3mm thick x 10mm A/F tiles on 2mm rubber with no rubber between) | 3.5 kgs | |

| CWP08/0404S | Cera-Wear Ceramic Wear Pad with CN B/L 8mm x 500mm x 500mm (Square pattern 4mm thick x 20mm A/F tiles on 4mm rubber with no rubber between) | 5.1 kgs | |

| CWP14/1004S | Cera-Wear Ceramic Wear Pad with CN B/L 14mm x 500mm x 500mm (Square pattern 10mm thick x 20mm A/F tiles on 4mm rubber with no rubber between) | 10.5 kgs | |

| CWP20/1208H | Cera-Wear Ceramic Wear Pad with CN B/L 20mm x 500mm x 500mm (Hex pattern 12mm thick x 20mm A/F tiles on 8mm rubber with no rubber between) | 13.5 kgs |