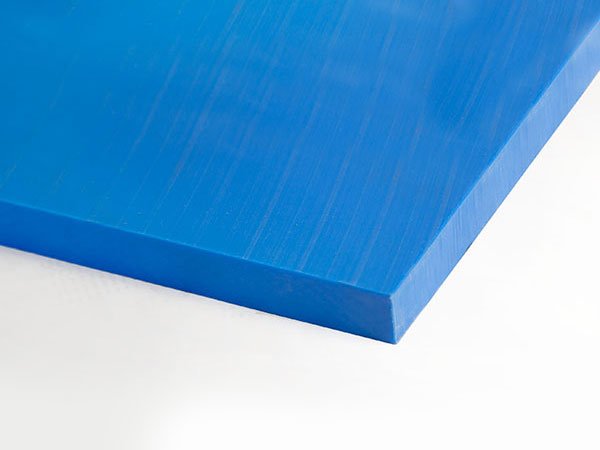

Reg-slide UHWMPE Wear Liners are a premium grade wear resistant, flow promoting polyethylene plastic liner.

FEATURES

Reg-slide UHMWPE Wear Liners are made from a premium Ultra High Molecular Weight Polyethylene plastic and will display good resistance to fine particle and sliding abrasion.

Reg-slide UHMWPE has a very low friction coefficient which results in excellent anti-stick properties which increases material flow and reduces the build-up of sticky materials.

Reg-slide UHMWPE is designed to be installed by mechanical fastening. It can be supplied as full sheets or cut liners as a custom engineered wear protection plastic lining system for your equipment.

APPLICATIONS

Reg-slide UHMWPE Wear Liners have been designed primarily for use as a flow promotion plastic lining system.

They are installed into equipment to reduce material build up and to protect steel surfaces from abrasion.

They are predominantly used in the Mining, Quarrying and Mineral processing industries, typically on the following equipment:

- Chutes

- Screens

- Hoppers and bins

- Feeders

- Stacker / Reclaimer buckets

- Conveyor Hoods

- Dump truck bodies

Reg-slide UHMWPE can also be used for any application which requires an anti-stick and abrasion resistant plastic.

TECHNICAL INFORMATION

| Polymer | UHMWPE | |

| Colour | Blue | |

| Specific Gravity | 0.93 | ISO 1183 |

| Hardness | 61° Shore D | ISO 868 |

| Tensile Strength | 20 MPa (min) | ISO 527-1 |

| Breaking Strength | 40 MPa (min) | ISO 527-1 |

| Elongation @ Break | 350% | ISO 527-1 |

| Temperature Range | -20°C to +80°C |

| Coefficient of friction (Dry vs Steel) Static | 0.15 | |

| Notches Impact Strength | 0.8mJ/mm² | ISO 179 |

| Impact Strength with 15° V-Notch | >100 mJ/mm² | ISO 179 |

| Thermal Conductivity | 0.41 W /m-k | DIN 52612 |

| Flammability | HB | UL94 |

| Insulation Resistance | >1014 Ω cm | DIN VDE 0303 |

| Surface Resistance | >1015 Ω | DIN VDE 0303 |

| Dielectric Strength | 45 kV/mm | DIN VDE 0303 |

| Arc Resistance | L4 Degree | VDE 0303 |

AVAILABLE SIZES

Reglin stock Reg-Slide UHMWPE Wear Liners in sheets in a range of standard thicknesses.

Reg-Slide UHMWPE Wear Liners can also be custom cut as per specifications and drawings and supplied with pre-drilled counter-bored holes to be fastened with UHMWPE Capped Bolts. See Custom Cut UHMWPE Liners.

| PART NUMBER | DESCRIPTION | WEIGHT (EACH) |

| REGSL010/3000 | Reg-slide UHMWPE Wear Liner Sheet 10mm x 1250mm x 3000mm | 35 kgs |

| REGSL012/3000 | Reg-slide UHMWPE Wear Liner Sheet 12mm x 1250mm x 3000mm | 45 kgs |

| REGSL020/3000 | Reg-slide UHMWPE Wear Liner Sheet 20mm x 1250mm x 3000mm | 76 kgs |

| REGSL025/3000 | Reg-slide UHMWPE Wear Liner Sheet 25mm x 1250mm x 3000mm | 95 kgs |