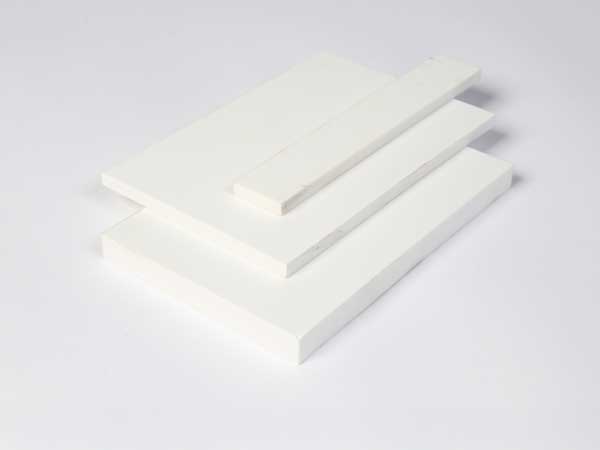

Premium grade wear resistant Alumina Ceramic Tiles designed for direct bonding.

FEATURES

Reglin High Density 92% Alumina Ceramic Tiles are a high-performance wear protection material designed for direct bonding to equipment surfaces exposed to extreme abrasion. Made from premium 92% alumina, these tiles provide exceptional resistance to sliding wear, corrosion, and fine particle impact, ensuring long service life in demanding industrial environments.

The dense, fine-grained ceramic structure offers superior durability and a smooth, low-friction surface that promotes material flow and reduces build-up within chutes, hoppers, and transfer points. Their excellent chemical and corrosion resistance makes them ideal for use in wet or dry process systems handling abrasive or corrosive materials.

Reglin alumina tiles maintain dimensional stability and mechanical strength at high operating temperatures, making them suitable for both process plant and material-handling applications. Precision manufactured to tight tolerances, they are supplied in a range of sizes and thicknesses for efficient installation and long-term performance.

APPLICATIONS

Reglin 92% Alumina Ceramic Tiles are used for lining and protecting steel surfaces in equipment exposed to abrasion and corrosion.

They are designed for direct bonding to create a smooth, durable wear surface that resists sliding wear and extends equipment life in both dry and wet process environments.

These tiles are commonly used across the mining, quarrying, mineral processing, grain handling, and bulk materials industries, where they protect against continuous wear caused by the movement of abrasive materials. They also perform exceptionally well in slurry handling systems, providing long-lasting protection inside chutes, pipes, bends and fittings.

They are suitable for a wide range of wear protection applications, including:

- Chutes, hoppers, and bins handling abrasive or free-flowing materials

- Transfer points and discharge chutes exposed to sliding or impact wear

- Pipes, elbows, and spigots in slurry and material transport systems

- Cyclones, separators, and ducting subject to high-velocity particulate flow

Reglin 92% Alumina Ceramic Tiles provide a durable and cost-effective wear protection solution, improving flow efficiency, reducing downtime, and extending the service life of critical process equipment.

TECHNICAL INFORMATION

| Alumina Content | 92% (min) | |

| Colour | White | |

| Density | 3.6 g/cm³ | |

| Hardness (Vickers) | 1100 kg/mm² | |

| Compression Strength | 2480 Mpa | |

| Water Absorption | 0% | |

| Fracture Toughness | 3.75 Mpa | |

| Thermal Conductivity | 18 W/m.k | |

| STANDARD TOLERANCES | ||

| Flatness | ≤ 0.2% | |

| Thickness | +/- 1.0mm | |

| Length/ Width | +/- 1.5mm |

AVAILABLE SIZES

Reglin stock Ceramic tiles in range of standard sizes.

| PART NUMBER | DESCRIPTION | WEIGHT (EACH) |

| CT06100150 | 92% Alumina Ceramic Plain Wear Tile 6mm x 100mm x 150mm | |

| CT13100150 | 92% Alumina Ceramic Plain Wear Tile 13mm x 100mm x 150mm | |

| CT25100150 | 92% Alumina Ceramic Plain Wear Tile 20mm x 100mm x 150mm | |

| CT50100150 | 92% Alumina Ceramic Plain Wear Tile 25mm x 100mm x 150mm |