Open transfer points at conveyor loading zones are unsafe and can cause damage to equipment.

Open transfer points are often encountered in mining and quarrying operations where ore is transferred from one piece of plant or equipment to another. These locations typically encounter the most ore spillage and in many applications are subjected to high wear and impact during operation.

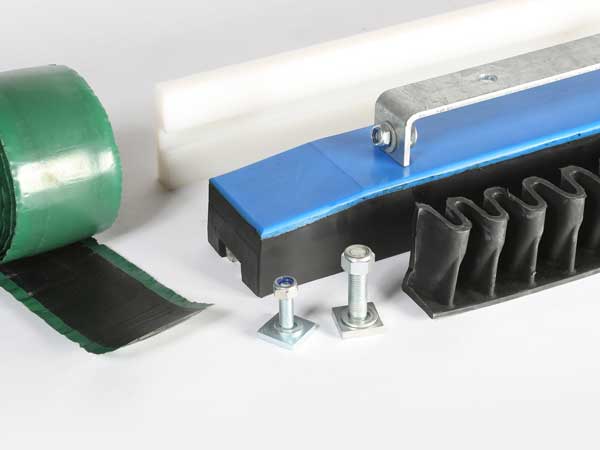

Chute Skirt Liners seal conveyor loading zones reducing wear on equipment and risk of spillage.

Installing the correct conveyor hard skirts in open transfer points at loading zones create an effective containment seal and controls the flow of ore directly onto the conveyor belt.

Reglin Chute skirt liners will result in a range of long-term benefits including:

Reduced Spillage

When correctly installed, Chute skirt liners reduce the gap between the structure and conveyor belt. This creates an effective containment seal minimizing the risk of material escaping and spilling out of the conveyor.

Protection of Equipment from Wear and Damage

Chute Skirt Liners are designed as a wear protection liner. They will protect the equipment structure behind from unnecessary wear, impact and corrosion and can be easily replaced when they are worn.

Decrease in Skirt Rubber Replacements

Skirt rubber is designed to act only as a secondary seal to contain dust and fine particles. Open transfer points can cause damage and sudden failure of skirt rubber as it is subjected to excessive wear and impact from high flows or large particle impact. Chute Skirt Liners protect the Skirting Rubber from this resulting in longer life and requires less change-outs.

Choosing the right type of Chute skirt liner for your application is critical.

Rubber Chute Skirt Liners

Rubber Chute skirt liners are required for applications subjected to a combination of high wear and impact.

Regline Rubber Chute Skirt Liners are made from a highly elastic premium rubber compound and will display excellent resistance to both sliding abrasion and large particle impact.

Polyurethane Chute Liners

Polyurethane Chute skirt liners are required for applications subjected to high wear and if sticky materials are encountered.

Regline Polyurethane Chute Skirt liners are made from an anti-caking, wear resistant polyurethane designed to promote material flow and will display excellent resistance to wet slurry and fine particle sliding abrasion.

OUR PRODUCTS