High Performance

& Premium Quality

High Performance

& Premium Quality

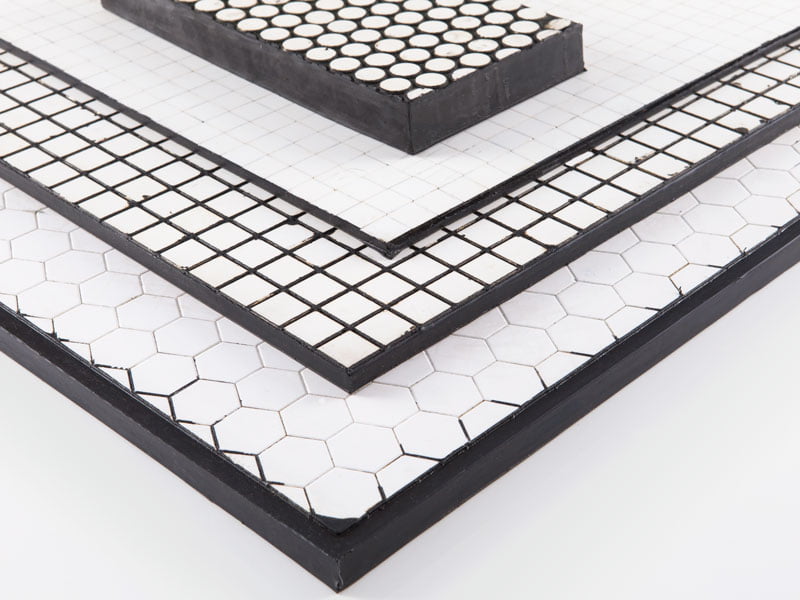

Reglin Rubber is a leading specialist supplier of rubber and ceramic products offering engineered wear protection and sealing solutions.

Located in Melbourne, Australia, Reglin Rubber has a vast product range and prides itself on keeping large inventory. This ensures we always have the right product for your application when you need it.

With our ability to dispatch quickly and comprehensive logistics network, Reglin Rubber can offer efficient delivery of products globally. We offer supply chain management from door to door, ensuring on-time delivery for our clients.

Reglin Rubber has a dedicated team of staff with both industry experience and expert product knowledge. We pride ourselves on excellent customer service and work with our local and global clients directly to ensure we always offer the right product solution for their application.

Reglin Rubber have a proven track record of delivering on-time cost-effective product solutions and are dedicated to supplying the right product for your application. We partner with our clients to achieve their goals, whilst also offering the highest value return.