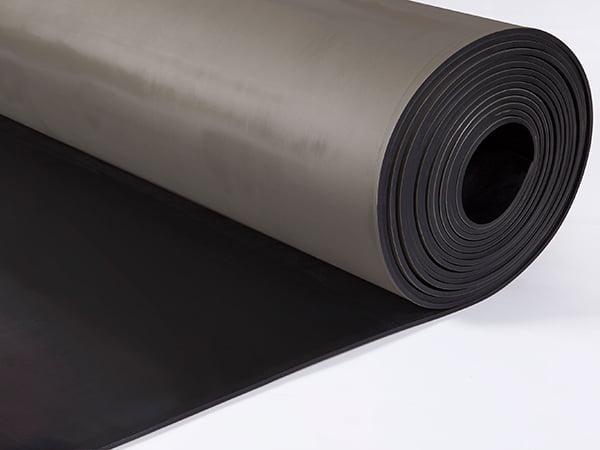

Regline 60 Lining Rubber is a premium grade wear and impact resistant 60 Duro rubber lining with a CN bonding layer

FEATURES

Regline 60 Lining Rubber is made from a highly elastic premium rubber compound and will display excellent resistance to sliding abrasion and large particle impact.

Regline 60 has excellent physical properties including cut and tear resistance. It will also display resistance to some mild chemicals, including acids and alkalis used in mineral processing. It has good ozone/UV resistance making it suitable for outdoor use.

Regline 60 features a specially formulated Neoprene based CN bonding layer to achieve ultimate adhesion when bonded to steel or rubber surfaces. The CN bonding layer is compatible with a wide range of Neoprene based rubber adhesives and allows for good bond strength to be achieved even in adverse conditions encountered on site.

APPLICATIONS

Regline 60 Lining Rubber has been designed primarily for use as a wear and corrosion protection lining system.

It is bonded to equipment to protect steel surfaces from abrasion and impact. It is predominantly used in the Mining, Quarrying and Mineral processing industries, typically lining the following equipment:

- Chutes

- Screen components

- Mills

- Scrubbers

- Trommels

- Trunnions

- Deflector plates

- Conveyor pulleys and idlers

- Magnetic separator conveyor belts

Regline 60 can also be used for any application which requires a wear and impact resistant rubber including the following:

- Mill seals

- Loading / Discharge socks

- Transfer and joining sleeves

- Impact curtains

- Variety of sealing applications

TECHNICAL INFORMATION

| Polymer | NR/BR | |

| Colour | Black with CN bonding layer | |

| Specific Gravity | 1.10 | ASTM D297 |

| Hardness | 60° ± 5° Shore A | ASTM D2240 |

| Tensile Strength | 17 MPa (min) | ASTM D412 |

| Elongation @ Break | 450% (min) | ASTM D412 |

| Abrasion | 60mm³ (max) @ 10N | ASTM D5963 |

| Temperature Range | -20°C to + 70°C | |

| Tear Strength | 80 N/mm (min | ASTM D624 |

AVAILABLE SIZES

Reglin stock Regline 60 Lining Rubber in a range of standard thicknesses and roll sizes. It can also be supplied in cut lengths, strips, pads and a wide variety of custom cut shapes and gaskets to suit your application requirements.

| PART NUMBER | DESCRIPTION | WEIGHT (PER L/M) |

| REG6003 | Regline 60 with CN B/L 3mm x 1500mm ( 10 L/M Rolls) | 6.2 kgs |

| REG6006 | Regline 60 with CN B/L 6mm x 1500mm ( 10 L/M Rolls) | 10.7 kgs |

| REG6010 | Regline 60 with CN B/L 10mm x 1500mm ( 10 L/M Rolls) | 16.5 kgs |

| REG60102000 | Regline 60 with CN B/L 10mm x 2000mm ( 10 L/M Rolls) | 22 kgs |

| REG6012 | Regline 60 with CN B/L 12mm x 1500mm ( 10 L/M Rolls) | 20.7 kgs |

| REG60122000 | Regline 60 with CN B/L 12mm x 2000mm ( 10 L/M Rolls) | 27.6 kgs |

| REG6016 | Regline 60 with CN B/L 16mm x 1500mm ( 10 L/M Rolls) | 26.4 kgs |

| REG6020 | Regline 60 with CN B/L 20mm x 1500mm ( 10 L/M Rolls) | 33 kgs |

| REG60202000 | Regline 60 with CN B/L 20mm x 2000mm ( 10 L/M Rolls) | 44 kgs |

| REG6025 | Regline 60 with CN B/L 25mm x 1500mm ( 10 L/M Rolls) | 43.2 kgs |

| REG60501800 | Regline 60 with CN B/L 50mm x 1800mm ( 10 L/M Rolls) | 103.7 kgs |